- Home

- Production Machines of Insulators

- Acoustic Emission System for Insulator Crimping Inspection

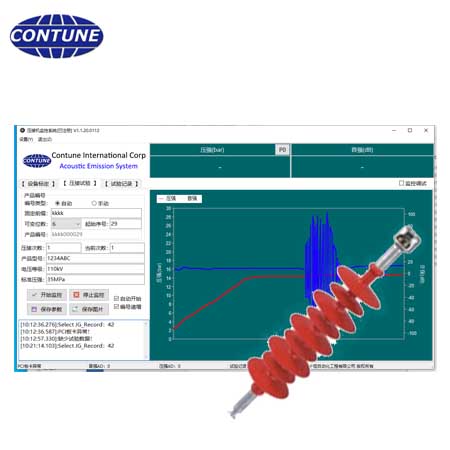

Acoustic Emission System for Insulator Crimping Inspection

The acoustic emission detecting system helps to detect the cracking noise of FRP core during the crimping of insulator fittings. It's used in the production line of insulators.

- General Details

- Technical Info

- Comments

- Related Products

What is an acoustic emission system?

It’s a detecting system for the crimping process of polymer insulators production.

Its full name shall be “Acoustic emission detecting system for polymeric insulators crimping”.

What can an acoustic emission system do?

This system helps the user to identify and judge if there are breaks or crack of FRP core in polymer insulator crimping. This will ensure the user to know those invisible cracks of FRP core and to pick out insulator products with discrepancies.

Who needs the acoustic emission detecting system?

This acoustic emission system is applied by manufacturers of polymer insulators. So this crimping detecting system is needed by insulator factories.

How does the acoustic emission detecting system work?

It’s a long story. Simply speaking, the sensors are attached to the crimping dies, which press the metallic fitting onto the FRP/ECR rod of polymer insulators. In this process, when the pressure is too big, the crimping machine presses the metal fitting too hard that cracks occur inside the fiberglass. These cracks or breaks in fiberglass are too tiny to be spotted by a human, but the sensors are very sensitive and it helps users to “hear the noise of cracks”. The signal is communicated to the controlling computer and our analysis software will show this great change in the curve so that the user will know.

Why do we need an acoustic emission detecting system? Can we do without it?

In the past when technology is not so advanced like today, manufacturers of insulators just crimp the metallic fitting with a standard crimping machine. The pressure value is often located after many times of trying and largely based on the experience of the technician. Even this, overload happens frequently, there are small cracks inside the FRP rods of insulators and causes failures of insulators in test procedure or in a real environment. This problem brings much loss to the manufacturers, both on money and in the reputation of the company.

Now when the acoustic emission detecting system shows up, users are able to identify the discrepancy insulators immediately and prevent the bad quality from being mixed to mass production. This helps a lot in the quality control system and saves the cost for the manufacturers in time, money, labor and efficiency.

This crimping detecting system is highly recommended for the factories of polymer insulators, especially for a new starter.

What is the price of an acoustic emission detecting system? Is it expensive?

No, it’s very cost-effective. Compared to the price of a crimping machine, the price of an acoustic emission detecting system only takes about one-fourth or one-fifth of a crimping machine QCPM-165. (See related products in above labels)

On what type of crimping machines can this system be applied?

This crimping detecting system is an optional configuration of our own crimping machine QCPM-165 for polymer insulators up to 400kV. For a new buyer, you can select this system when you purchase our crimping machines. There is a sales pack for both crimping machine and acoustic emission system.

For an existed crimping machine, it can be added to the crimping machines of Uniflex, FinnPower, and some Chinese brands. Normally, as long as the signal can communicate, this system is universal to all crimping machines. Insulator manufacturers can select this crimping detecting system with or without a crimping machine.

Name: Acoustic emission detecting system

Appliance: for cracks detection in polymeric insulators crimping

Model: C-AES-20

Manufacturer: Contune International Corp Ltd

Country of origin: China

Report saving function: Yes

Customizable report function: Yes

Curve function: Yes

Language of software: Chinese / English / Russian

Spare part list:

- Control panel

- Computer

- Power distribution box

- Knobs

- Indicator

- Signal amplifier

- Communication board

- Sound sensors

- Acoustic probe

- Signal wires

- Controlling software

CRIMPING MACHINE 165 FOR COMPOSITE INSULATOR PRODUCTION

The crimping machine is applied in the production line of high voltage composite insulator (polymer insulator) to crimping metallic end fittings to FRP of the insulator. Model 165 is available for an insulator with voltage up to 800KV

33kV Composite Pin Insulators

33KV composite pin insulators are used on 33KV high voltage overhead power distribution lines. These pin insulators are made by FRP core, silicon rubber, and metallic fittings. On the bottom side of the fitting, it is where we call pin, the pin has a screw which is used to fix the insulator onto the cross-arm. On header fitting, it usually has a groove shape to fix conductors.

Laser Marking Machine For Composite Insulators

Laser marking machine is applied in marking words, logo, symbol, character and etc on multi-material items. It has advantage of wide adaptability, fast speed and high precision.

11KV Composite Pin Insulator

11KV composite pin insulators are used on 11KV high voltage overhead power distribution lines. These pin insulators are made by FRP core, silicon rubber, and metallic fittings. On the bottom side of the fitting, it is where we call pin, the pin has a screw which is used to fix the insulator onto the cross-arm. On header fitting, it usually has a groove shape to fix conductors.